Clann Mhór

The Kelly and Larguey Ledger

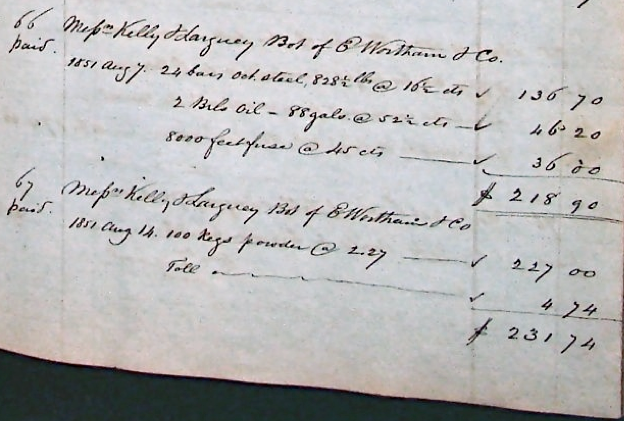

When the original contract for the Blue Ridge Tunnel was voided in early 1851, the Board of Public Works instructed Claudius Crozet to keep track of all expenses and pay the contractor, Kelly and Larguey, on a “cost plus” basis. Thus a clerk was assigned the task of logging all the expenses in a ledger book. Thankfully, this ledger book has survived the many years and is kept in the files of the Library of Virginia in Richmond.

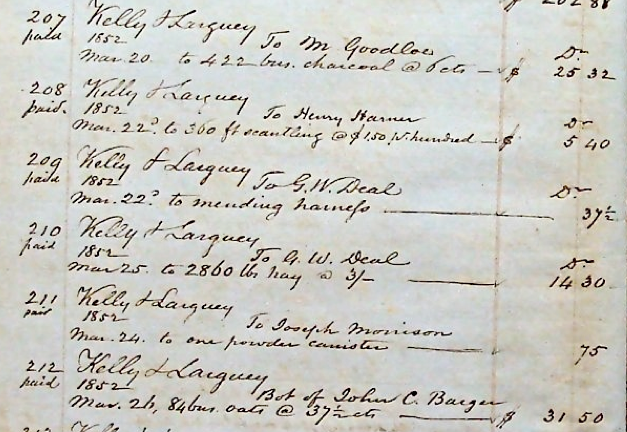

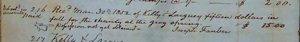

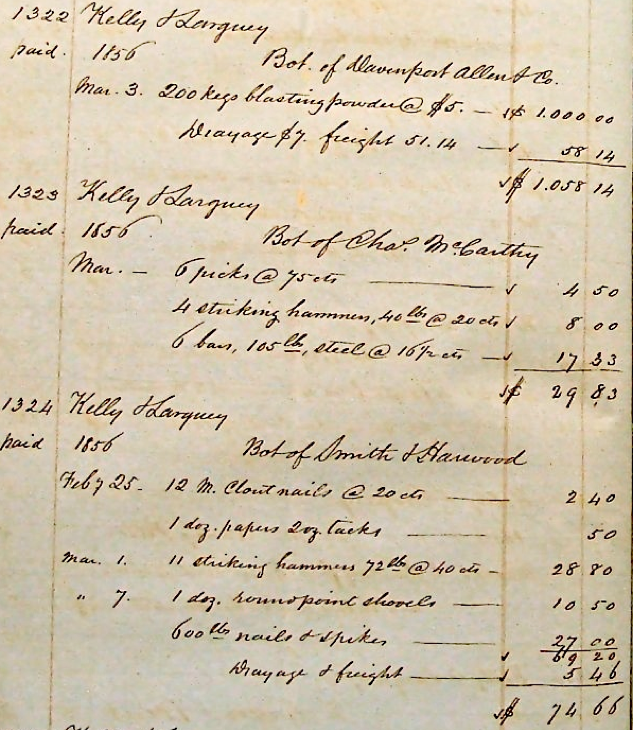

The thousands of entries in the ledger book paint a fascinating picture of the many activities going on daily at the Tunnel itself. As the various suppliers delivered their goods to the contractor, entries were made to record the date and cost of each item. The entries list not only the obvious tons of steel and iron that was handled by the work crews, but also a wide variety of other materials charged to the cost of digging the tunnel.

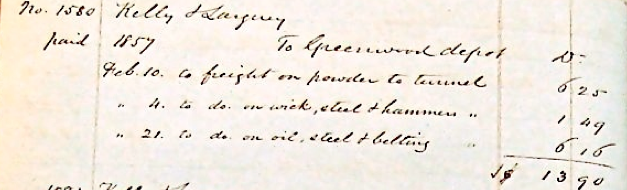

Each month hundreds of kegs of blasting powder and thousands of feet of fuse were delivered. The regular pattern of delivery of these two items alone provides a real sense of the tremendous effort involved in blasting the rock out of the tunnel.

There are weekly deliveries of hundreds of bushels of charcoal - presumably for the blacksmith. Many gallons of oil are used for the hydraulic pumps that both pumped water out and fresh air into the tunnel.

The oil for the lamps and lanterns were listed as whale oil, sperm oil, and lamp oil. Other oils listed were boiled oil, turf oil, British oil, lard oil and sweet oil. There were frequent entries for balls of candle wick and pounds of lamp wick.

Many types of timber were delivered including planks, oak planks, pine planks, scantling, square edge lumber, sheeting, oak, lathes, and railing. Fasteners included kegs of nails, fire nails, closet nails, horse nails,spikes, pounds of rivets, grosses of screws, square nuts and washers. Other building material included four light window sash, shingles, panes of glass, putty, butt hinges with screws.

The many types of tools used by the workers included wheelbarrows, shovels, picks, anvils, bellows, tongs, vise, ladders, chain weights, hatchets, augers, jack plane, moulding plane, drawing knives, spoke shaves, ladders, hammers, riveting hammers, ratchet drill, compass saw, bow saw, hack saw, crowbars, files, square files, round files, hard files, horse rasp, curry combs, lanterns, lamps, tin dipper, buckets, oil cans, rope and tape line. Every month dozens of replacement hammer and pick handles were delivered to the job.

More unusual items include salt peter, borax, turpentine, linseed oil, salt, lime, Mustang liniment, and “four inch India rubber belting.” Several times a horse was bought by the contractor, one was a “grey horse,” another was listed as a “dark bay horse (warranted).” Obviously the contractor had other teams of horses as there were weekly deliveries of large quantities of hay, corn and oats. Several times a local landowner was paid for “months of pasturing of horses.”

Other services provided by local folks included moving a feed house, building a shanty, building an observatory, joining copper pipes, patching and hooping pipes, and daily service as a machinist at the tunnel.

John Larguey was a partner in the contracting firm, he was listed as a “Boss” on the tunnel payroll, and apparently he ran a general store near the tunnel. The ledger book lists many purchases from him, including match paper, matches, rope, writing paper, reams of paper, best medium paper ruled, memo book, roll book, blank book, lead pencils, bottles of ink, paper tacks, thread, needles, tape, soap, candles, iron pot, buckets, tin cups, paint brushes, dusting brushes, varnish, shears, and hoop iron.

Separate line items were listed for Drayage and freight for many deliveries. When items were brought up from Scottsville, tolls were listed for the use of the Plank Road. Early on, drayage and freight were listed from Charlottesville or Woodville to the tunnel. These were generally for manufactured items that were shipped from Richmond on the Virginia Central Railroad as far as the railroad tracks went at that time, then loaded onto horse-drawn wagons for the rest of the trip to the tunnel. Later, when the trains went as far as the new Greenwood Depot, the goods still had to be unloaded and brought by wagon to the tunnel near the top of the mountain.

Looking through this ledger book, it becomes obvious that many local businesses did a brisk trade with the contractors blasting the tunnel and laying the track. This commerce, along with the payroll to the construction workers, added a lot of cash into the local community. Later, as the trains began to run, new towns were built up around the railroad depot stops. The town of Afton, just outside the east portal of the Blue Ridge Tunnel, is one example. It was never as big a town as when the hundreds of Irish workers and their families lived and worked there. But even after they moved on, Afton became an important shipping point for the many local farmers and businesses.